The following article reproduces the slides and notes of a presentation delivered by Eric Worpe at the MGCC T Register’s ‘Rebuild’ event held earlier this year.

Types of Water pumps

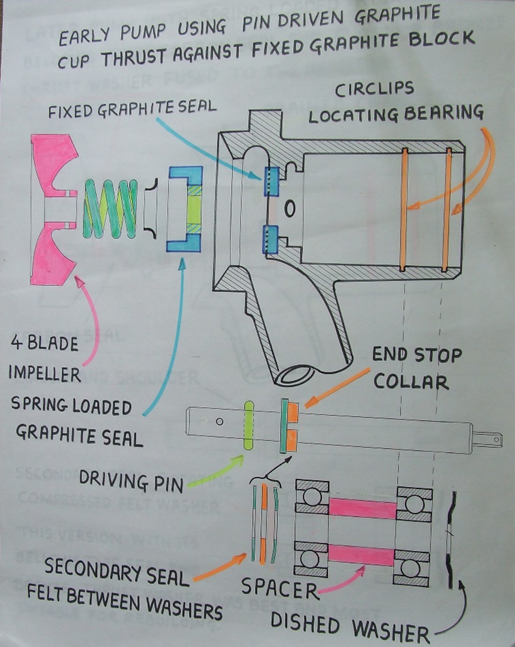

1.1 Early pump

The diagram below shows an early type pump using a pin driven floating graphite cup, thrust against a fixed graphite block secured in the pump housing. The floating cup is spring loaded through a dished washer and a rubber washer which seals off the cup from the drive spindle. The rubber washer is not shown in the diagram.

The graphite seal is long lasting but the rubber washer hardens and allows coolant to leak past the spindle into the drainage chamber. Coolant should then escape through the drainage hole but can also enter the adjacent ball bearing.

To limit leakage into the ball bearing, a secondary seal comprising a felt washer between two steel washers is keyed to the spindle. The outer periphery of the felt washer rubs against the wall of the drainage chamber, but soon loses its effectiveness in sealing against leakage into the ball bearing.

This type of pump’s life is determined by the rubber washer, which it seems is no longer available.

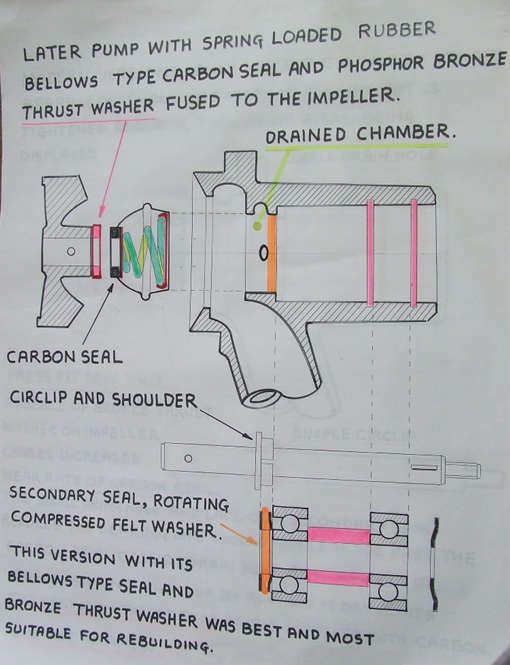

1.2 Later pump

The diagram below shows the later pump with a spring-loaded rubber bellows type graphite seal and a phosphor bronze thrust washer fused to the impeller.

The bellows has a tapered outer section which makes for an effective seal in the pump’s housing.

A similar secondary seal, as in the early pump is again used, with the felt and steel washers clamped between the circlip and the inner race of the ball bearing. The shoulder of the spindle is an integral part and serves to locate the spindle relative to the ball bearing. The bronze thrust washer is polished to reduce wear of the carbon block.

This type of pump is the most suitable for rebuilding.

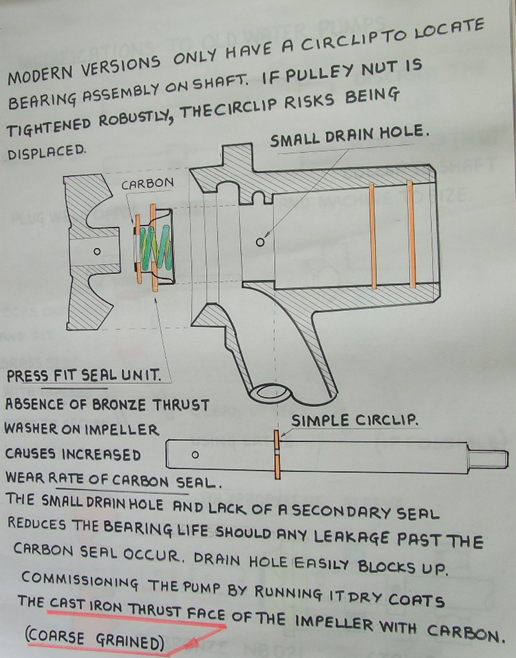

1.3 Modern version

The next diagram shows the modern version, which seems to have been made to a price with quality a secondary consideration.

It uses a press fit cartridge with a spring-loaded graphite seal thrust against the cast iron face of the impeller. The shoulder on the spindle has been replaced by just a circlip, which can be displaced if the pulley nut is tightened robustly.

The secondary seal has been omitted and the drain hole reduced in size, which results in it rusting closed when leakage occurs. A blocked drain hole and absence of a secondary seal limit the life of the ball bearing.

One is advised to commission the pump by running it dry. This coats the thrust race of the impeller with graphite. The graphite seal thus becomes sacrificial in laying a graphite film over the coarse grained surface of the impeller.

2. Suitability of pumps for rebuilding and modifications required

The later and modern versions of the pump can be rebuilt with either a bellows type seal Ref. NB021, or a press fit cartridge seal type FB-12L.

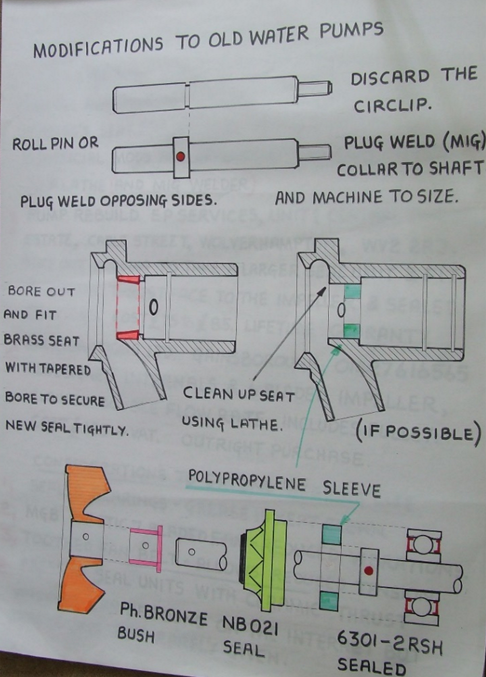

The NB021 version will need to use the impeller with a bronze thrust face which ought to be polished and this version may also need the housing for the bellows machined to give a clean surface. Unfortunately, the NB021 has parallel sides that fit in the housing and relies on a substantial rim to effect a seal, hence the need to machine the seating. If the seating is too badly corroded, one could bore out the pump’s body and fit a brass seat, preferably with tapered sides for the bellows.

The circlip can be replaced by a machined collar, which is either plug welded to the shaft or fixed using a roll-pin. The front face of the collar should be aligned with the front face of the previous circlip as this sets up all the relative locations of bearings and seals to the impeller. The drain hole in the pump’s housing can be opened up and a further restriction to any leaked coolant contaminating the bearings could be provided for by a pressed in sleeve located as shown in the diagram.

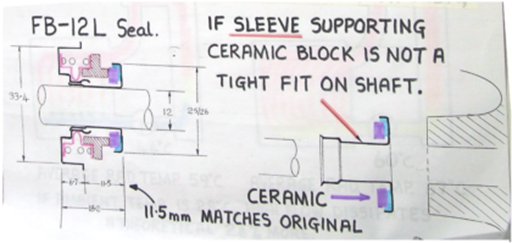

The replacement cartridge seal type FB-12L seems to be an exact fit for the pump. It is intended for a 33.4 mm dia. bore-hole and a 12 mm dia. shaft. The displacement from the flange seating to the impeller is 11.5 mm which also matches the original set up. It also has a self-contained ceramic thrust block for the graphite seal. For this to be effective the support sleeve for the ceramic block needs to be a tight fit on the 12 mm dia. spindle. However, the spindle area in front of the impeller is often corroded, so a sealant should be used to secure the sleeve.

I suspect that a suitably machined press mandrel may be needed to press the body into the housing and the sleeve on to the shaft at the same time. If using a sealant between the shaft and the sleeve, the impeller will need to be in position before the sealant hardens.

3. Conclusions

A simple rebuild is possible on the “later pumps” by replacing the rubber bellows with the NB021 seal and using sealed bearings type 6301-2RSH. However, this assumes that the pump’s housing seat is not corroded and the impeller has a bronze thrust face. A corroded seat for the seal could be lightly machined and the seal secured with silicon rubber. The NB021 relies on a somewhat thick flange which obscures the input water passage, unlike the original bellows seal which relied on a tapered seat and a thin rim.

The newest replacement pumps would need some machining to make them more robust. Incorporating a bronze bush in the impeller and fitting a collar to replace the circlip as well as a polypropylene sleeve to seal off the drained chamber seems a lot of effort.

Looking for a more suitable seal on e-Bay was frustrated by the adverts only referring to seals for specific cars, whilst internet searches revealed images of seals with only a few dimensions. Then by chance on a Chinese AliExpress site I came across the ultimate seal, the FB-12L. The real improvement of this seal is the incorporation of a ceramic thrust face for the carbon block, so a bronze thrust face on the impeller is not necessary.

The FB-12L seal is designed for a 12 mm diameter shaft and a 33.4 mm (1 + 5/16”) diameter bore hole. It can be used with both types of impeller as the impeller’s thrust face now acts only as a back stop for the inner sleeve of the cartridge.

The inner sleeve may need to be sealed with silicon rubber.

Considerations to extend bearing life.

- Use sealed bearings 6301-2RSH, keeps grease clean.

- Fit MGB 7 bladed plastic fan, reduces out of balance vibrations.

- Try a toothed fan belt, which allows one to set a reduced belt tension.

Commercial services.

Pump rebuild – E P Services, Unit 1, Central Trading Estate, Cable Street, WOLVERHAMPTON WV2 2RJ Offer a lifetime guarantee.

Racetorations Ltd., Gainsborough, 01427 616565. Uses 6 bladed impeller and includes pulley, outright purchase.

6 bladed impeller

Is a 6 bladed water impeller worth fitting? A high coolant flow results in a more even temperature distribution throughout the engine and reduced possibility of “hot spots”. Pre 1960s engines which did not benefit from Nodular cast iron, were prone to cracking if exposed to thermal stresses, so an increased flow would seem beneficial.

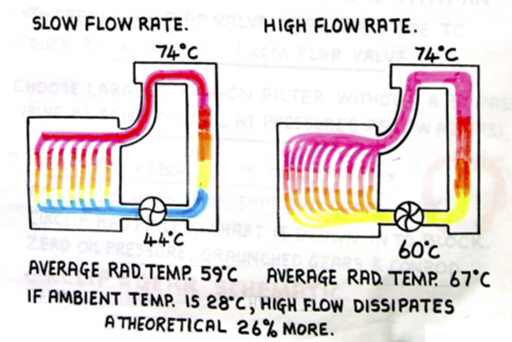

Would a 6 bladed impeller improve cooling? Uncertain, but a theoretical idea based on Newton’s law of cooling suggests it could. Consider an engine running with a thermostat fully open at 74 degrees C (see diagrams). A low coolant flow would develop a large temperature difference across the engine and radiator. A high flow would reduce the temperature difference, resulting in a higher average engine and radiator temperature. The higher average radiator temperature would be able to dissipate more heat, thus enabling the engine to work harder for the same maximum coolant temperature.

N.B. Newton’s law of cooling states the rate of cooling depends on the temperature excess.

Editor’s note:

There were failures on some pumps supplied by Racetorations Ltd. I recall that one of these was experienced by the late Jerry Birkbeck when driving his TC. The pulley became detached and hit the radiator.

Before purchasing a Racetorations pump for my TF1500 I contacted the company to try and establish the reason for the failures. I was told that one of the parts (I think it was the pulley) was a bought in item and the company now manufactured this ‘in house’.

Since fitting the pump to my car, I have not experienced any problems.