BOTH BORN IN 1946

BOTH STILL GOING IN 2023

A LONG JOURNEY RECOUNTED

It was September 1962 and I had left school to join the real world! Thanks to a family friend, I was able to secure a place on a 5-year Engineering Apprenticeship with Ferranti Ltd at Hollinwood, Lancashire. For the first 6 months we were in the Training School being taught how to file, saw, and use Lathes, Milling and Shaping machines and then to use these skills to make a complete set of Engineers tools, including Die and Tap holders, Calipers, Gauges and even a Junior Hacksaw. These items are still in my study at home.

The next 2 years were spent working in each of the eight manufacturing departments of the High Voltage and Power Transformer Division and earning our first pay packet, which enabled us to become independent to enjoy our free time playing cricket and rugby and at weekends, hiking and climbing, as well as visits to the local dance halls and public houses.

It was during this free time that I worked with and met two of my still best friends, one of whom owned a 1953 MG TD, but with a 1500cc engine from an MGA. Enthused by this sports car and with a little help from my parents and grandparents, I now had the means to start looking for an M.G.

The search began and by the 31st January 1965 I put a £10 deposit on a 1946 MG TC in Clipper Blue from Archway Engineering in Manchester. On the 8th February 1965 I paid a further £40 and my journey began. The car was used as my daily transport to work, but more importantly was the freedom to travel around the UK in my spare time. Many epic journeys were undertaken; sailing holidays in Salcombe, coastal climbing near St Ives, numerous visits to the Lake District, including a few journeys over Hardknott Pass. Also, two annual overnight drives down to the Earls Court Motor Show.

As they say, all the best plans are often not achieved and a promotion at work led to my going to Canada to work at Ferranti-Packard and Ontario Hydro. On my return after 9 months a new job as Overseas Sales Manager was taken up and my girlfriend Ann agreed to marry me. This was despite memories of an epic journey in DBL 54 over the Derbyshire moors at night in the pouring rain, where she had to hold the passenger door closed when going over bumps, and to keep tightening the hood screws to the windscreen, finally having to manually operate the wipers when the motor packed up.

All this early motoring came to an end in August 1971 when the car was gracefully retired into my father’s garage in serious need of some body work and with a plan to have the engine taken out to try and sort out why the car was not as powerful as another friend’s bog-standard TC.

DBL 54 in semi-retirement

Fast forward to October 2007 and the condition of my father’s garage deteriorated, forcing me to remove the TC and bring it up to our double garage at Littleborough.2008 saw the commencement of a very slow strip down of the TC and it soon became obvious that a bigger place was needed to store all the bits, so a new shed was built. However, for the next 10 years I was employed to run a small Cable manufacturing company, which provided more funds to feed the TC rebuild. Progress only really started in the middle of 2019.

The first order was to Andrew Turner for the refurbishment of carburetters, and which produced the first surprise of the project in that the two carb bodies were of different lengths. Fortunately, Andrew was able to find a matching pair. The carburetters, as bought, never had any manifold or filter canister fitted. A new filter system is yet to be decided.Next up were the shock absorbers which I entrusted to Raj Patel to recondition. I also organised for a complete rebuild of the original radiator.

It was at this stage that I carried out a more detailed look at the engine and gearbox to assess what would be involved in its restoration. I started with the original Guarantee plate on the battery box, which gave the original car number TC/0552 and engine number XPAG 1340. TC/0552 agreed with the stamping on the front nearside chassis. However, the details on the Buff registration book, which was a continuation book, recorded an engine number of XPAG B 66320 with a 1344cc capacity?? The cylinder head was the correct 22952 so that was encouraging.Ed’s note: This would have been a replacement engine and bored out to +100 thou.I then looked at the engine block to check its casting details, which were MM in a Diamond and the 7A8 (Jan 7 1948). Finally, I cleaned up the circular disc on the engine block, which was a Morris Motors Limited Engine Branch no. 77037 and an inner disc showing Type XPJM! which I understand had an original 1140cc capacity. This does then perhaps explain why my TC, as bought, was much slower than my friend’s TC. The gearbox was stamped XG782 which I understand was a standard XPAG.Ed’s note: This engine would probably have been bored to 1250cc.

Fortunately, I was able to sell both the engine and gearbox and subsequently placed an order with Ron Ward for a replacement. Ron lives just 3 miles from me and I continue to have regular discussions on all things MG TCs and life in general. Subsequently, I placed an order with Hi-Gear for a new 5-speed gearbox. Ed’s note: Terry lives in East Lancashire, on the border with West Yorkshire – Ron lives in West Yorkshire, on the border with East Lancashire – 3 miles apart.

Above: The XPJM engine which came with the car. Below: Two ‘shots’ of the XPAG engine (minus air filtration) now fitted.

At the beginning of 2020 the next major decisions involved the restoration of the tub and all other metal components and chassis. Early pictures of my attempts to repair the rear wings and running boards and a driver’s side panel showed my lack of skill in this area and painting was a complete no go for my capabilities. Carl at Moss suggested I contact Steve a SH Restorations in Cross Hills, which I did and I asked him to restore the front wings, valance, petrol tank, doors, bonnet, scuttle, and fire wall and inspect the tub, metal, and wood, and quote me for checking the chassis alignment and condition prior blasting and coating.

On inspection, the tub was in need of all the metal panels, including door skins, and only a few of the wooden sections were useable. So, I did a costing using catalogue prices for the replacement wood and metal parts to make the tub serviceable. In the meantime, SRH heard that Hutsons had a near complete tub, the order for which had just been cancelled, and I bought this at a good price and sold the old tub for someone to use as a basis for restoration. On the brighter side, SRH were able to restore all the original metal parts, except the rear wings and running boards, which were bought new from NTG.

The chassis was found to be in very good condition and the tolerance, as measured from the flat front chassis to the front cross-member, was deemed to be good. It was then media shot blasted and finally coated in satin black.

The crown wheel and pinion condition was checked by my local specialist Garage and replaced into the housing, before the axle was cleaned and painted in satin black.

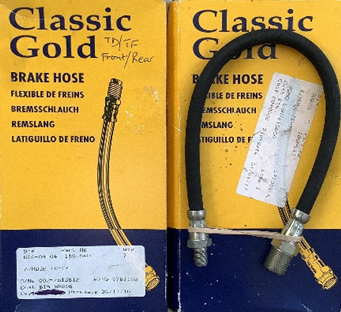

The return of the chassis in Feb 2020 allowed me to start the process of building up the rolling chassis, starting with the splitting and greasing between layers of the springs and then re-assembly – a messy job. This was followed by Raj Patel’s dampers. Next came the braking system with new brass body master cylinder, new brake lines, wheel cylinders and shoes. Then the handbrake assembly including new cables, pawl and ratchet parts were installed.

The externally refurbished brake drums were given an internal sensitive surface clean pending the return of the front axle, so I could do an individual bedding in on each drum of the new brake shoes.

The same cleaning and painting process was applied to the front axle before being taken down to Eric Worpe for him to replace the axle spindles (from Bob Grunau), kingpins and a full axle inspection. Eric made a very suitable wooden box so I could have the axle shipped back to me, to enable me to continue to replace the unit onto the chassis. Eric also advised me to use taper roller bearings on the front axle and sealed units on the rear axle. (Supplied by Mad Metrics).

Finally, the Half shafts were Inspected for wear. I knew the offside was good as I had replaced it and its oil return bush before I laid the car up in the early seventies. On checking the nearside I decided to replace the bearing and half shaft just in case.

While I had good access to the chassis, I did a first install of the new wiring harness, renewed both engine and gearbox mounts and the recently returned radiator, including the repainted stay bars, and checked the front spring pin condition.

The silencer and rear section of the exhaust were fitted, as were both front wing stays and the bulkhead support brackets. This meant that I now had a moveable rolling chassis with brakes, original Brooklands steering wheel, column and box all connected and original wheels and tyres, ready for the next fitting of engine and body. Good timing I thought!

July 2020 saw me shift attention to my body, having a few new parts (namely a new Aortic Valve and a re-enforced Aorta). Covid had been delaying this operation since January but the hospital found a slot for me at the end of the month. I was up and about after the fifth day of the operation, and home on the 7th day. Talk about fast-track planning, but Covid circumstances prevailed.

So, with the help of my very patient wife, recovery began. However, and as you can imagine, the next 6 months or so meant light duties. I therefore set about organising more orders for new or restored electrical items, dashboard from Andrew Denton, windscreen polishing to remove scratches, restoration of starter motor, regulator, and an exchange dynamo with taco connection from Chris Wallis. All the original chrome parts for re-chroming (except the radiator shell, which I would be sending to Peter at All Metal Polishing).

It was now Jan 2021 and it became obvious that anything other than light work on the car was not recommended, so I decided to ask Steve at SHR if he would now collect the new engine from Ron Ward and fit it, together with the new gearbox and prop shaft. Then as originally specified and agreed, to complete the first fix of the tub and body parts to ensure a good fit. Afterwards, complete the painting of all the body parts and do a final fit of the tub, petrol tank, rear wings, running boards, scuttle/firewall and floorboards. This to be followed by a second fit of the front wings, leaving only the front valance and separate bonnet sections painted for me to assemble, once the restored radiator shell was repaired and chromed.

Steve understood my circumstances and was agreeable to this extra work related to the fitting of the new engine and gearbox. He duly finished the work and delivered the complete car back to me at the end of April 2021.

It was now all down to me to complete the project with a deadline of May 2022 when I had booked a slot with A.S. Pickering to install the interior, including the restored original seating, carpets, new hood and side screens and a full tonneau, again using the restored original hood frame and side screens. I had already had the original brass bodied SU Fuel pump restored by Peter Cole, choke and slow running and starter cables restored by JJ Cables and as mentioned earlier, I had the radiator shell repaired and re-chromed by Peter at All Metal Polishing in Hull and what a cracking job he did.

Steve Baker helped me to procure the set of 5 new 19inch MWS wheels, complete with Blockley tyres, as well as finding me a restored dual oil pressure/water temp gauge.

I decided to do a loose fit connection of the hoses and clips, also leaving the final tightening of the radiator securing nuts to help when I was installing the restored radiator shell. I next fitted the dynamo and fan belt, SU pump, ignition coil, distributor, regulator, starter motor and battery and their wire connections. The tidy fitting of all wires into the regulator took a couple of attempts and now looks good. Sticking with the electrics, I next finished the installation of the wiring to the front lighting, horn, and spotlight, then up the front wing braces and similarly to the rear lighting and petrol tank float unit and separate indicator lamps. All the lighting units were individually earthed in addition to their earth in the main harness wiring. The new petrol line had a first fit install whilst I still had the rolling chassis and now could fashion both front and rear connections to the pump and tank.

Finally, I fitted the front wings to the running boards and on to the wing braces, which enabled me to run the wires through the headlamp brackets. At this stage I finally fitted the radiator and shell together with the lamp brackets and stay bars to the bulkhead support bracket and left these loose until I got around to assembling the bonnet, which proved quite easy. By lots of ‘give and take’ I found an acceptable fitting, followed by fitting the front valance with some metal cutting of the valance to suit the position it was going into. The bonnet used its original catches and once I had discovered that the rear rubber corner pads had to fit in between the wing and body the catches worked first time. Not forgetting to tighten up the radiator hose clips to the engine.

At this point I had almost forgotten about the difficulty of putting the front section of the exhaust on and whilst I had to loosen both silencer and remove the tail section, I had memories of doing this way back when I had to fit a new front section.

Sticking to the mechanical work, I had left the re-assembly of the windscreen to nearly the end, as this was quite a challenge, really requiring more than one pair of hands, some very fine cable wires and a lot of Vaseline and a determination not give in.

Speaking of which I omitted to mention that I had a little problem with some newly made track rod and the tie-bars which had dodgy threads, so they were rejected and I settled for the original set and fitted new tie and drag rod ends. I also retained the original steering box with new shims. As my first drive in the car just after getting its MOT in Dec 22 the loose steering wheel approach came flooding back and convinced me to stick with the original setup.

As it worked out, the last area for attention was the dashboard, both relating to the fixed wiring layout (which does now seem to be a little busier than the old one I pulled out, particularly as I was not able to have the two bulb holders soldered to the back of the chrome panel so had to screw them to the dashboard) and I found that the new dash board harness was a little short of wire lengths, particularly earth wires. The other problem I had, seemed to relate to the slightly thicker harness wires and smaller diameter holes into which multiple wires had to go into, particularly the socket set accessory plugs. The wire sizes and numbers going in to a 9 post Regulator made the job of fitting quite a few more wires more difficult and to look neat.

The veneered dashboard supplied by Andrew Denton required very little changing and its upper curve was near perfect to match the Hutsons inner dashboard section. This was later to prove very helpful as Pickerings requested that I had to fit the leather beading onto the top and rear of the dashboard; comments so far, say it looks good.

The final connecting of the main harness to the dashboard was carried out by the G clamp method and this proved workable for 95% of the harness wiring. However, the red four main headlamp and rear stop and tail lamps had to be twinned to form only two wires to facilitate connection into the ignition terminal. Care was required to feed the bundle of wires back under the scuttle whilst ensuring the dashboard fitted snugly and then tidying them up and securing them, where appropriate, under the scuttle. I had earlier fitted a Lucas DB10 Flasher/Relay unit, but I could not get this to work properly, so I took off the wires required for the indicators and did a straight connection with a standard flasher unit and switch which all seems to work ok.

It was at this point that I then fitted the assembled windscreen into position and was thankful that SHR had drilled the holes into the scuttle and test fitted the cowl brackets, with the result that it fitted perfectly and even the wiper motor worked. (However, this only lasted until one of my trial runs with the car saw the motor expire.) When switched on, fortunately, all the ancillary bits worked.

Being the first item restored, the carburettors were fitted to the engine almost as soon as I got the car back from SHR. However, the next job was to finally connect the 3 dashboard control wires onto the carburettors and linkages. Prior to this I had spent more hours trying to get the timing marks on the engine pulley and distributor set to the correct position. I was then able to put some petrol into the tank and spend many an hour trying to get them balanced and the engine running evenly and with the mixture and plug colour somewhere near to ok. Fortunately, and whilst not perfect, the car seemed to want to jump into life when started. As a backup, I had pre-arranged to book the car into my local Garage and MOT station for them to give it a full mechanical and electrical checkup and alignment of the headlamps and finally an MOT.

The owner has a PA and services a number of customers who go racing each weekend.

The end of May arrived with undue timing but the car was booked into A S Pickerings in Bradford to have the interior and original seats recovered, new carpets installed and a new hood, side-screens and a full tonneau cover fitted. As is usual when you have a wife and two daughters, they had already instructed me to have the car painted in Jaguar Indigo and now this needed the interior to be French grey leather, with dark blue carpet, however I got to choose the black hood, side screens. and tonneau. I must admit, it does look wonderful.

Above: French Grey upholstery with dark blue carpet in DBL 54. Below: Jaguar indigo paint finish.

The car left Pickerings in early October 2022 and was delivered to the local Garage. Unfortunately, their auto electrician identified that the PLC6 was actually sparking, so a replacement was ordered and substituted. Otherwise, the car was MOT’d in early December and the owner of the garage had his best mechanic drive the car a short distance to my home. So, a Happy Christmas was had by all.

I am sure that this long journey could fill a book with other earlier exploits from my driving days but I have just about saturated my poor literary skills in the writing of this journey. So, it only remains for me to mention a number of people who have made this journey possible in addition to those already mentioned.

John James – Totally T type 2 Pete, Martin, Mark – Octagon Car Club

Steve Hill – SH Restorations

Eric Worpe

Ron Ward

Terry King – Victoria Garage

Steve Baker

David – Pickerings

John Pritchard

And last but certainly not least my wife Ann who always encouraged me to complete this DBL 54 Journey.

Terry Midwood

List of Suppliers mentioned in the article.

Andrew Denton www.mgashframes.co.uk

Andrew Turner https://www.su-carbs.co.uk

Blockley Tyres https://blockleytyre.com

Chris Wallis [email protected]

JJ Cables Limited 01926 651470

Mad Metrics [email protected]

MG Octagon Car Club www.mgoctagoncarclub.com

NTG Motor Services Ltd https://mgbits.com

Pickerings of Bradford www.aspickering.co.uk

Raj Patel 0116 244 8103

Steve Baker https://www.stevebakermg.co.uk

SH Restorations www.shrestorations.co.uk