Dick Knudson described how he and his son Erik fitted replacement rear trunnion repair tubes to Erik’s TA in the April issue of TTT 2. Not an easy job, especially if you haven’t tackled it before.

The rear trunnion housing can be found to be badly worn on some cars and is worth checking, since the consequences of the main leaf of the rear spring parting company with a worn housing are not pleasant.

The cause of wear is lack of lubrication and this is generally brought about by the use of grease in the grouped nipple lubrication system, which can dry out and effectively block the thin bore of the brass lubrication pipe, which is designed for oil, not grease. It doesn’t help that the rear trunnion lubrication points are the farthest away from the oiling nipples which are situated towards the front of the car.

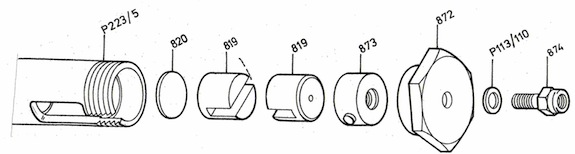

The TA and TB share the front and rear trunnion suspension arrangement with the Triple-M cars and some of the part numbers are the same as demonstrated below:

| Part Description | MMM # | TA/B # |

| Trunnion roller | 819 | MG681/125 |

| Washer for ditto | 820 | MG681/126 |

| MG681/127 | ||

| Distance piece | 873 | 873 |

| Cap for x-tube | 872 | 872 |

| Greaser/set screw | 874 | 874 |

So far as I can tell, the parts are identical even though the part numbers are different in some cases. The exception is the washer (820 for MMM) – MMM cars have only the one, but the TA/B has two MG681/126 (outer washer) and MG681/127 (inner washer).

A drawing for the MMM arrangement follows and after that is a photograph of the MMM components.

If you are wondering about the trunnion housing in the photo, it is not a repair tube but a sawn off length from an old cross tube. I had a complete cross tube made some years ago and I kept the old pieces (never throw anything away!).

When fitting trunnions make sure that the slots are a good sliding fit on the main leaf and that the trunnions themselves are a good fit in the housing (tube). When the cap is tightened (remember that it is a left hand thread on both sides) there should be no detectable lateral movement.

Before fitting the leaf spring I get an old length of spring and after tightening everything up I make sure that the trunnion rollers are rotating OK. Having checked this I then dismantle and fit the spring.

I have had a small batch of phosphor bronze trunnions made with a 1⁄4” slot (OK for rear spring and for front if you have replacement springs on the front). The price is £6.50 per trunnion, which is cost price but I would appreciate a donation of £1.00 per trunnion for my TTT 2 fund – they are still keenly priced compared with those elsewhere.

One of the rear trunion housings of my TA broke years ago before I bought it, but the other side is original. Since I must replace one side, should I assume that the original side is old and worn and replace it at the same time? I bought new rear springs. Perhaps I should get new front springs as well since the car steers very poorly. Again your advice is welcome. Please let me know how to purchase a set of your phosphor bronze trunions. Thanks, Wayne

Wayne,

I would replace both housings as a matter of course. In any case I doubt if you would be able to purchase a repair kit for just one side as they are normally sold in pairs. Yes, if the springs are worn they will have the effect of steering the car for you. In particular you should look for wear in the front pin which should be a snug fit in the spring ‘eye’ and wear in the front trunnions/trunnion box.

I’ve sent you an e-mail about the trunnions and I’ve also mentyioned that I do high quality front pins. Regards, JOHN JAMES

About 45 years ago as a young man with newly purchased MG TB Tickford. I had the trunion problem. I was in contact with someone who rebuilt a TC using two cars.He sold me the rear shackle springs and this remained on the car until recently when I have started a rebuild.

I gave a machinest friend a drawing and he manufactured the two rear trunion replacement parts for me. They have been fitted and am now embarking on the chassis rebuild. I have seen these replacement parts available from mgbits and I would suggest also replacing the rear springs (or at least the main spring, as they wear badly over time)

I discovered the same problem with my TA when rebuilding it. A fellow rugby player ran an engineering company and with the aid of my drawing the apprentice produced two repair sections. The outlay was a couple of pints for the apprentice.

The repair is still working well some thirty years later.