MG TDs and TFs have a Lockheed brake master cylinder combined with a fluid reservoir. This reservoir has a limited capacity and access to check the brake fluid level and add fluid is difficult in that the cylinder is located just below the floor near to the foot pedals. To gain access the carpet must be folded back and a metal cover, screwed down onto the flooring, must be removed. This gives access to the filler plug through a small hole in the flooring.

Even with the steering wheel removed it is difficult to position one’s head to see down into the opening and pretty well impossible to add fluid and check the fluid level. The only solution appears to be one which involves a mirror, torch and a purpose made dipstick.

Ed’s note: Keith Douglas’ solution was published in the October 2010 issue of TTT 2, available to read here.

The fitting of a remote reservoir addresses both access and potential low fluid levels, eases the bleeding of the brakes, and enables the car user to see any drop in fluid level by simply lifting the bonnet.

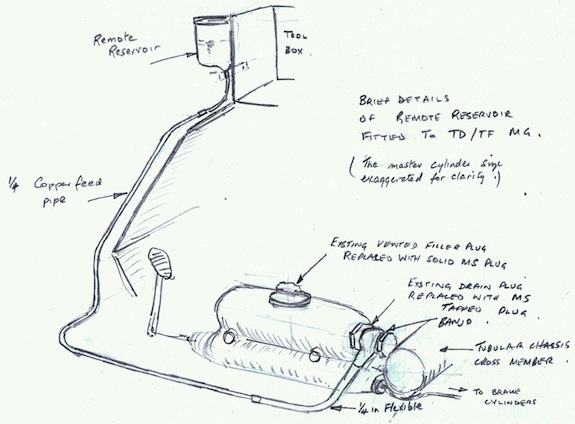

The sketch below shows how I installed a remote reservoir to my TF.

The installation was not that easy as access is from above, and this necessitates removal of the seats, steering wheel, drive and transmission cover and the timber floor panel on the driver’s side.

The master cylinder sits in a fairly restricted space between the pedal box and a tubular chassis cross member.

These restrictions were further compounded by the additional supports on the cross member for the 5 speed gearbox fitted onto my car, and I found the best solution involved a banjo off the front of the master cylinder (photos 1 and 2) with a 1⁄4 in feed pipe up (photo 3) to the remote reservoir which I located on the outside face of the tool box under the bonnet (photo 4).

Photos 1 & 2: two views of the cramped space; the banjo fitting off the front of the master cylinder can be clearly seen in both photos.

Please note that no modifications to the existing master cylinder are required other than the replacement of the filler and cleaning plugs.

However as the work necessitates removal of the master cylinder the owner may take the opportunity to have the cylinder refurbished by a specialist, say Past Parts of Bury St Edmunds, beforehand.

MATERIALS USED

Remote reservoir Single chamber remote reservoir by Girling. 7/16 inch 20 tpi UNF connection. F 7/16 20 tpi to 1⁄4 inch pipe. I purchased mine from Europa Spares on the Internet.

Feed pipe 1⁄4 copper pipe of length sufficient to wind down to a location beneath the master cylinder where it is connected to a 1⁄4 inch flexible pipe.

I used standard copper as this is easy to bend using a pipe bending tool.

Flexible pipe and banjo 13 inch long purpose made flexible pipe with a female union at one end to make connection to the 1⁄4 copper feed pipe via a 7/16 inch, 20tpi UNF brake nut and a 1⁄4 BSP banjo and bolt at the other end.

Ideal Hose and Safety Ltd at Rugby made up the flexible hose connected to the banjo and banjo bolt, but no doubt there are others who can do this.

Connection to master cylinder.

Remove the existing drain plug at the front of the master cylinder reservoir. You can drill and tap this to take the banjo bolt but the interfaces must be perfect as brake fluid leaks readily through weak points.

I replaced this plug with one from a Morris Minor restoration company and drilled and tapped this out to take the banjo bolt. Owing to the tight space between the front of the master cylinder and the circular chassis cross member I found it necessary to reduce the thickness of the head of the banjo bolt to enable a fit.

I used standard new copper washers and a big spanner to ensure a tight leak proof fit. In my case the location of the 5 speed gear box connection very much dictated the angle of the banjo.

Existing filler plug. This is a 1&1/8” 20 tpi UNF aluminium plug 3⁄4 inch deep with a vent hole. I tried sealing this but was not assured that it would not leak in time so I replaced this with a solid steel plug from the same Morris Minor restoration company who supplied the other plug. I fitted fibre washers which gave an adequate seal with the new plug well tightened down.

Filling: I left off the new plug from the original filler hole and only put this in at the last moment during filling before the brake fluid spilt over to ensure that there was little or no air trapped in the master cylinder reservoir.

Note: I then made a suitably large opening in the floor above the master cylinder so that I could see the end connections and tighten the bolts if necessary. I covered this with an aluminium plate screwed down to the floor. This being beneath the carpet, it cannot be seen.

Since fitting this system in January 2011 I have found it so useful in not only having the comfort of being able to see the brake fluid level at any time but in bleeding the brakes. It is so simple to top up the remote reservoir during this process.

Additional Note: During the course of this work I discovered that the same Lockheed master cylinder was used on a number of cars in the 50s most notably the Morris Minor. MM specialists often replace the drum brakes at the front with discs and as the reservoir is insufficient they have been fitting a remote reservoir for some time. They use standard 3/16 copper pipe and connect this direct into the predrilled plug they screw into the front of the master cylinder. They have room to do this not having a tubular cross member in the way.

Recently another MG Kilsby member has fitted this system to his TF and in this case used 3/16 copper pipe connected to a flexible pipe and a banjo. I used 1⁄4 inch to ensure I could overcome the air lock during initial filling.

Noel Lahiff

Hi All, I made this kind of conversion aloso for TC0660.

Closed the lid by soldering the cap tight and made a pipe connection on the lid, first part flexible, rest copper brake line material going up in the tub (in visble) with a see through brake fluid container installad in the tool box.

No more dirt in th masterbrake cylinder, easy to check, fill and renew.

Dirk

I have just fitted a similar remote reservoir, but I used the 3/16 pre-drilled blanking plug (and unvented top cap) available from the Morris Minor centre in Bath. Even with a five speed conversion, there is just enough room to bend the 3/16 copper pipe through 90 degrees, without restricting it. I took the pipe up inside the car, clipping it to the roll hoop, and then up through the battery box floor. The remote reservoir was mounted on the inner edge of the battery box, having moved the battery over to one side. The reservoir came from JJC race and Rally, and the female fitting to take the 7/16 UNF male fitting on the bottom of the reservoir, and a 3/16 pipe is their part number HU7A. Flow appears to be more than adequate down a 3/16 pipe. And no more risk of spilling brake fluid on the leather!!

Hi! Read with interest re remote reservoir for MG-

Is it possible to remove the reservoir from under the car so as not to have to remove seat, floor, gearbox cover etc? I believe I saw an article on this some time ago. Do you remember in which magazine it was referred to? Mine is a 1954 TF with 5 speed bx conversion.

Plan to go on holiday to France this Summer and reservoir never touched for 10 – 12 years! Regards Peter Jeffers

I see the need for an extension of the reservoir capacity but can you tell me please why the pipe is not connected to a replacement cap at the top rather than re-engineering the end plug?