Introduction

Thank you to everybody for your positive comments on the articles so far. Their aim has been to help owners understand the fundamental issues behind the problems caused by modern petrol, better equipping them to put in place measures to mitigate the symptoms. The next three articles summarise my suggestions on possible solutions. The main thing to remember is that our cars are not the same, differences have accumulated with the passage of time as various owners have made tweaks and mods to make them run better. The severity of the problems experienced by owners varies immensely, even between the same models of car. A solution that may work well for one car may not resolve the same problems in another. The suggestions in these articles should be taken just as that, suggestions for people to try; they are not intended as solutions to be blindly adopted.

Owners mainly experience two problems when using modern petrol, 1) the engine spluttering to a stop in slow moving or stop-start traffic, particularly on hot days, 2) The hot restart problem where a hot engine cannot be restarted after it has been switched off for about 5 minutes. Some owners also experience burnt exhaust valves and cracked heads, problems also related to the use of modern petrol.

The Cause? A larger fraction of modern petrol is volatile at temperatures below 50°C. compared with classic petrol. Ultimately, this leads to the Weak Running problem described previously. The Manchester XPAG tests also identified a second problem, Slow Combustion, this appears to be at its worst at normal road driving speeds. It increases the temperature of the cylinder head, the exhaust manifold and the under-bonnet temperature (hence the burnt valves and cracked cylinder heads) and it makes the Weak Running problem worse.

These problems do not affect modern cars. Firstly, their computer-controlled fuel injection systems provide a more accurate, finely atomised and better mixed charge of fuel. Secondly, petrol is circulated from the petrol tank to the injectors under pressure which increases the petrol’s boiling point. Unused petrol is circulated back to the tank to cool down.

In this, the first of the three articles which suggest possible solutions, I discuss basic steps that can be taken to help avoid fuel vaporisation. The later articles will cover re-tuning the engine to help reduce the severity of the potentially more damaging Slow Combustion problem.

Petrol Volatility

Petrol is not a single substance, it consists of many different hydrocarbons, each with a different boiling point. If you heat modern petrol, some components will start to evaporate or boil at relatively low temperatures, whilst others will still be liquid at temperatures well above the boiling point of water. Unfortunately, at typical under bonnet engine temperatures of around 50°C, a significant volume of modern petrol can evaporate. This leads to vapour forming in the fuel system, particularly problematic, when it is in the carburettor jet, which makes the mixture very weak causing the engine to falter and stop.

The most effective way to address this problem, is to use a fuel that is less volatile at low temperatures. Easier said than done! The table and graph show the list of fuels that were tested at Manchester and the percentage by volume that evaporated when the temperature reached 50°C (hot running) and 75°C (a temperature possibly reached in stop start traffic). Those on the left hand side of the graph with a lower volume evaporating are the best fuels to use.

|

Fuel |

% Evaporated |

% Evaporated |

|

Avgas |

3% |

22% |

|

50% Toluene |

4% |

24% |

|

Sunoco Optima 98 |

5% |

22% |

|

1960 Petrol |

9% |

28% |

|

Branded 95 Octane with 10% kerosene |

15% |

36% |

|

Branded Super Grade with ethanol |

17% |

36% |

|

E10 |

18% |

46% |

|

Branded 95 Octane (Batch 2) |

20% |

46% |

Unfortunately, with the exception of Sunoco Optima 98, the top four performing fuels are either not available or not legal for road use. For the first of these three fuels, less than 5% evaporated at 50°C and, if used on the road, they would not suffer from the Weak Running problem.

In contrast, at this temperature, nearly 20% of a well-known brand of 95 Octane petrol (Brand 1) evaporated, increasing to 46% at 75°C. Certainly, sufficient to cause the Weak Running problem. Indeed, it was this fuel that showed this problem during our tests.

In defence of this petrol, the tests at Manchester were run in March and it is highly probable that it was a more volatile winter grade. It is also worth noting that adding 10% kerosene to this petrol reduced the volatility by 5% at 50°C and 10% at 75°C, not a cure, but a significant improvement.

Unfortunately, in practice you do not know what petrol you are filling your car with. This was demonstrated at Manchester where two batches of the same, well-known, brand of 95 octane petrol, bought from a filling station close to the University within days of each other, proved to be very different. One contained ethanol, the other did not and the XPAG ran very differently on each of these batches.

Again, unfortunately, other than avoiding winter grade fuel, adding kerosene or using a bespoke fuel such as Anglo American Oil Sunoco Optima 98, there is little that can be done to ensure you are using a low volatility petrol. However, if you do suffer from volatility problems, it is worth trying a different brand, grade or filling station.

Keep the Petrol Cool

One means of avoiding the Weak Running problem is to keep the petrol under the bonnet as cool as possible.

Needless to say, the engine cooling system should be working efficiently. Once every two years or so, flush the engine and radiator with clean water. If fitted, ensure the thermostat is working properly. Wetting agents in the cooling water are also claimed to help reduce temperatures.

At Manchester we only experienced the hot restart problem, not the slow moving or stop-start traffic problem. During the tests, the temperature measurements taken from the carburettors were not sufficiently high to indicate vaporisation would have caused a problem during normal running.

The tests suggested the hot restart problem was mainly caused by hot gases from the inlet manifold raising the temperature of the carburettors. When you stop a 4-cylinder engine such as the XPAG, one cylinder will have its inlet valve open allowing residual hot gases to leave the cylinder and flow back into the inlet manifold. With no air flowing through the engine bay coupled with heat soak from the engine, it is sufficient to raise the temperature of the fuel, such that a significant percentage will boil in the carburettor jet.

This has a double negative effect. Firstly, it blows liquid fuel out of the jet which runs down the inlet manifold; secondly, it prevents the carburettor from delivering the correct mixture. Try to start the engine, it briefly coughs into life, running rich as the liquid fuel in the inlet manifold enters the cylinder, then it stops because of the weak mixture. Sometimes, it is possible to restart the engine using the choke and after a few coughs and splutters, normal running returns as cold petrol fills the float chambers.

One possible solution when stopping the engine for a short period is to blip the throttle, turn off the ignition while the engine is still revving and open the throttle. This will let cold air enter the cylinders before the engine stops, but at the risk of having it run on.

The cause of the stop-start traffic problem is different. Even though the engine is lightly loaded and not generating a lot of heat, there is little airflow under the bonnet, allowing temperatures to increase. At the same time the flow of fuel through the petrol pump, petrol hoses and float chambers is low, giving more time for it to heat up and start to vaporise. This is typical of the problems seen by owners, their cars run without problems in moving traffic and only start to misfire and stop when the traffic flow drops to a near standstill.

The best way to address this is to ensure the minimum volume of petrol is held under the bonnet. Keep hoses short and avoid “reservoirs” such as large fuel filters, etc. Ensure the fuel hoses, the air inlet and components holding petrol, are placed away from hot parts of the engine and, if possible, in the cooler air flow.

Use ducts or baffles to direct cold air onto the fuel system components, heat shields to prevent radiant heat reaching them. Only insulate parts of the fuel system as a last measure. Insulation does not stop the heat flow, it only slows it down; so when the engine stops, the heat will soak in and it will then take longer to cool down, possibly making the hot restart problem worse.

Insulate hot parts of the engine, e.g. exhaust manifold and exhaust down pipe as it will help reduce under bonnet temperatures as well as preventing heat reaching critical parts of the fuel system.

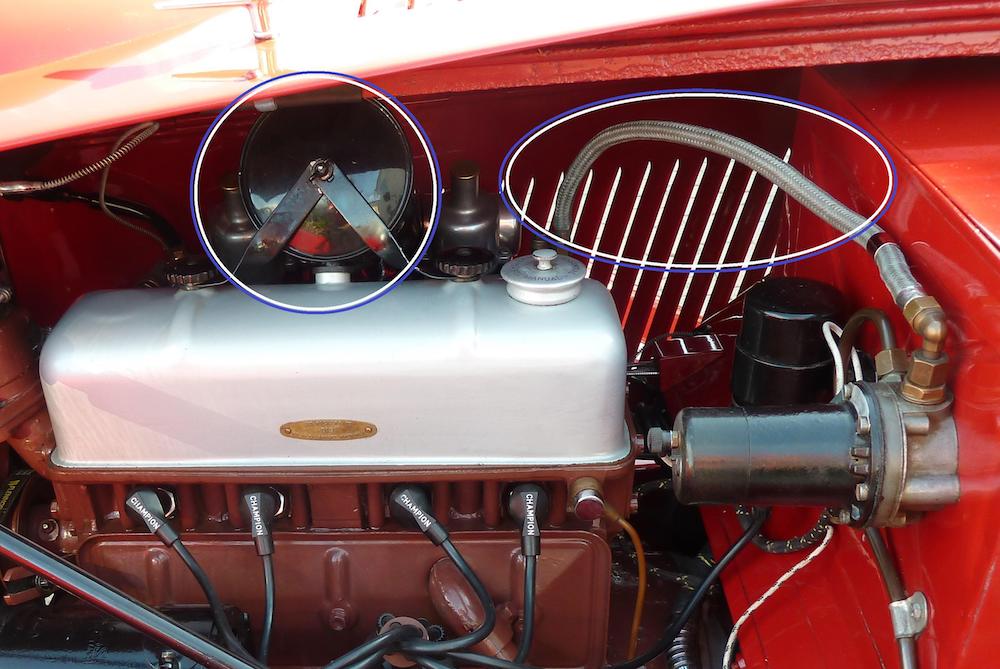

Unfortunately, on the standard MG TC, the petrol pump, cross pipe from the petrol pump to the carburettors and air intake are in the hot air at the top of the engine, not the best place (see previous photo). For example, although not original, pancake filters fitted directly to the carburettor inlet that draw colder air from the slits in the bonnet would be better.

Although I do not suffer from the hot restart problem, when switching on the ignition after a short stop, the petrol pump will sometimes continue to click as it tries to pump against the petrol vapour in the fuel pipes or cannot suck vapour from the feed pipe. This shows the potential dangers of running petrol hoses through the hotter parts of the engine bay.

Early in its production, the fuel pump in the original MG TF was changed from a low pressure pump fitted under the bonnet to a high pressure pump fitted at the rear of the car. The reason for doing this is not clear. However, when pumping a liquid it is always better to push it rather than suck it as this avoids cavitation and bubbles. In older cars, where the petrol pump is fitted under the bonnet, it may be worth considering following the example of the TF. Not only will this reduce the problem of cavitation and bubbles in the petrol, the pressure in the fuel lines between the pump and carburettors will be around 50% higher reducing the volume of fuel evaporating at under bonnet temperatures.

A warning – if you do re-route the fuel lines between the tank and carburettors, ensure that at least one part of the circuit is above the top of the petrol tank otherwise you may find petrol syphoning out of a parked car.

Ironically, in slow moving traffic, electric fans may make matters worse. They will switch on as the water in the cooling system gets hot, probably around 90°C and blow this hot air under the bonnet, further heating the fuel system. If an electric fan is fitted, it should be placed so as not to blow hot air onto the fuel system components. It is also recommended that it is fitted with a run-on so it continues to operate, blowing colder air, after the engine has stopped.

One clear message from the Manchester tests was that it was not obvious which parts of the fuel system get hot. For example, the thermal camera images showed the float chambers to be relatively cool, even though they were close to the inlet manifold whilst the choke levers were surprisingly hot.

If you are planning to investigate ways to keep your fuel system cool, it is worth buying an infrared thermometer.

Information can be found at:

https://www.google.co.uk/search?q=infrared+thermometer) and also, a multi-meter with a thermocouple https://www.google.co.uk/search?q=multimeter+with+thermocouple). These will allow you to look to identify hot spots in the fuel system after the car has stopped. By extending the thermocouple wire into the cockpit, the multi-meter can be used to monitor spot temperatures on-the-move.

Driving Style

When I learned to drive, the instructor impressed on me the need to use the gears. Modern cars with their variable cam timing, turbo chargers and computer managed fuel injected engines are very flexible and will run and accelerate in virtually any gear. While the long stroke XPAG is a very flexible engine, it does not run as efficiently over the rev range as it may appear.

A petrol engine, such as the XPAG typically only converts about 1/3 of the heat energy in the petrol into power, the remaining 2/3 of the heat goes into heating the engine, exhaust and cooling system. By driving the car such that the engine runs most efficiently, it not only saves petrol, but also helps reduce under bonnet temperatures, avoiding petrol vaporisation problems.

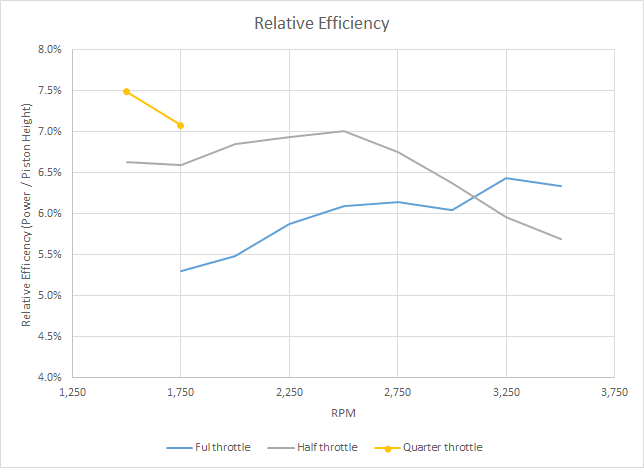

At Manchester, the height of the suction piston in the carburettor provided a measure of the volume of petrol entering the engine, the dynamometer measured the power output. Dividing the power output by the height of the suction piston, for each of the throttle settings and engine revs, gives a relative measure of the percentage of energy in the petrol that is being converted into power. The higher the percentage, the better. This is shown in the graph below for the 95 octane petrol.

This shows how much less efficient the XPAG is below 3000 rpm running on full throttle compared to half throttle. An indication of the Slow Combustion problem. It also shows how the efficiency at half throttle starts to drop above 2500 rpm, dipping below that of full throttle above 3100 rpm. This is caused by the throttle butterfly restricting the airflow into the engine.

As my driving instructor advised, when driving your car, use your gears. Avoid the use of full throttle below 3000 rpm, change down, and do not let the engine rev on part throttle, change up!

Conclusion

The volatility of modern petrol at relatively low temperatures is the ultimate cause of classic cars stopping in slow moving traffic, especially on hot days, and the hot restart problem. This article has suggested a number of steps that can be taken to help mitigate these problems.

Because of the variations in forecourt petrol, choosing a specific brand or grade does not provide a reliable solution. For low mileage cars, Sunoco Optima 98 is a good choice. This is an ethanol free fuel with a long storage life and which is less volatile than pump fuel at typical under bonnet temperatures.

Sunoco Optima 98 is available from Anglo American Oil Company Ltd. a specialist supplier of a wide range of both leaded and unleaded petrol. All fuels are available in 25lt drums with a selection available in larger sizes. Delivery can be made throughout the UK, using a hazardous freight carrier. In addition, they stock a range of oils with high ZDDP content blended with classic cars in mind.

Orders can be made direct with Anglo American Oil Company via their web shop (www.aaoil.co.uk) or by telephone on 01929 551557, where you can also talk to their technical team about your individual requirements.

NOTE: The law limits the amount of petrol that can be stored in a garage, or anywhere within six metres of a dwelling. Households are allowed to store up to 30 litres of petrol for private use without informing your local Petroleum Enforcement Authority (PEA). That comprises up to 20 litres in two ten-litre metal containers plus up to 10 litres in two five-litre plastic containers.

An alternative is to add between 5% – 10% kerosene (paraffin or heating oil) to the petrol as this reduces the low temperature volatility. If you live in the UK remember, you can do this legally for cars produced before 1956, but you will need to apply to HM Customs and Excise for a Concession. Write to:

Mr John Loughney, Excise, Stamps and Money Businesses

HM Revenue & Customs

3rd Floor West

Ralli Quays

3 Stanley Street

Salford

M60 9LA

………requesting a “General Licence to mix hydrocarbon oils under Regulation 43 of the Hydrocarbon Oil Regulations 1973 (SI 1973/1311)” giving your name, address, model and dates of production of the model of your vehicle.

However, adding kerosene reduces the octane rating of the fuel. At the 5% to 10% level, especially if a super grade petrol is used, this appears not to cause pinking problems with a standard XPAG. The possible effect on higher compression engines is discussed in the last article.

The second problem, Slow Burning is potentially more damaging to an engine because it overheats the valves and cylinder head. Hot valves may also contribute to pinking in higher compression engines. Furthermore, this problem appears at it worse during normal road driving when the extra heat generated by the engine can contribute to the Weak Running problem.

The next two articles discuss the effect of different fuels and how the carburettors and ignition system can be tuned to reduce the Slow Burning problem.

Paul Ireland

Whilst we are on the subject of petrol, this yellowed parchment filtered to the top of my “must keep” pile of “useless information which should be binned” (according to Mrs J!).

Never throw anything away I say, you never know when it will come in handy. Well, forty years later it has indeed come in handy to fill some space between Paul Ireland’s fuel article (so, very relevant) and Don Walker’s TF restoration article.

It probably dates from 1977, since there is a reference to “the last two years” and the last of the prices is December 1975.

Current price for ‘four star’ in the UK is around £5.52 per gallon. It reached its highest ever level in April 2012 when it cost an eye-watering £6.45 per gallon – phew!

In Northern Norway, we thinned Diesel with Aviation fuel which is in fact paraffin. Also heating oil is mentioned and that has been used in diesel cars illegally. What would be the result of a 10% mix of diesel since that is available on the forecourt?

Excellent article, thank you. Have you ever considered the possibility of the vapor lock occurring at the fuel line where it lies next to the muffler (TD)? The entire muffler lies just inches from the fuel and the line is situated in such a way that air cannot easily flow around it. Just curious.

Regards

Tim Burchfield

TD12524

TD26711